Challenges:

Traditional put-away costs workers a long time to find out the most suitable slot for numerous goods in the vast warehouse. They decide a put-away place based on their past experience. When a type of products need to change their usual slots, operators cannot timely find another suitable put-away location.

Solution:

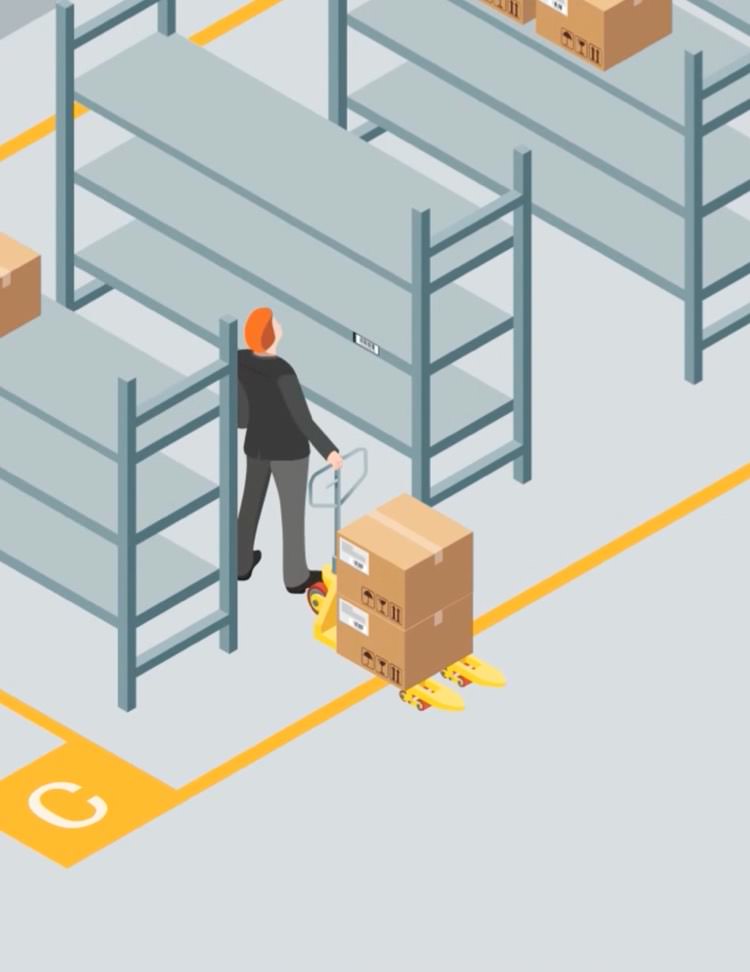

In warehouse management, Chainway mobile computers solve this trouble by changing the put-away method from manual to automate. It scans products' 1D/2D barcodes or RFID tags to assign all batches of products to their suitable storage slots, provides warehouse workers with the shortest put-away path based on GPS, and transfers this information to the backend server under wireless connectivity (3G/4G/Wi-Fi).

Results:

2. Warehouse workers and managers have access to real-time inventory level anytime so that warehouse space utilization can be optimized.

3. Out-of-stocks will never happen for warehouse supervisor can arrange rapid replacement of goods into the appropriate location based on accurate inventory data.