-

Productos

Computadoras Moviles

Modelos- MC62 Computadora móvil (Android 13)

- MC95 Computadora móvil (Android 12)

- C66 Computadora móvil (Android 9 / 11)

- C61 Computadora móvil (Android 9 / 11)

- MC50 Computadora móvil (Android 12)

- MC21 Ordenador móvil

- C90 Computadora móvil (Android 10)

- C71 Computadora Móvil (Android 8.1 / 11)

- C70 Ordenador de Mano

- C70 Terminal de Datos Móviles de Termometría

- C75 Computadora Móvil con Impresora

- C6000 Computadora móvil (Android 10)

Computadora móvil (Android 13)

Sistema operativo Android más avanzado, diseño de teclado más flexible, nivel de protección y duración de batería más fuertes.

Computadora móvil (Android 12)

Rendimiento potente. Más duradero y rentable.

Computadora móvil (Android 9 / 11)

Mas Poderoso, Más Extensible, Más Avanzado en Todos Los Sentidos

Computadora móvil (Android 9 / 11)

Easy and Flexible Data Entry, Remarkable Data Capture Performance

Computadora móvil (Android 12)

5G · Android 12 · IP67

Ordenador móvil

Más fácil de usar, más rentable, resistente y duradero

Computadora móvil (Android 10)

Pantalla más grande, peso más liviano, rendimiento más fuerte.

Computadora Móvil (Android 8.1 / 11)

Excelencia Sin Precedentes

Ordenador de Mano

Fuera de lo Ordinario

Terminal de Datos Móviles de Termometría

Medición de Temperatura de Alta Precisión en un Segundo

Computadora Móvil con Impresora

Brillante cuerpo moderno, impresión móvil eficiente

Computadora móvil (Android 10)

Robusto, Portátil y Extraordinario

Lectores RFID de Mano

ModelosLector RFID 5G UHF (Android 12)

El lector RFID portátil más potente de Chainway, que establece nuevos estándares para el rendimiento y la eficiencia de RFID

Lector RFID incorporado

El último lector manual RFID compacto y ligero

Escáneres RFID UHF

Potente rendimiento UHF y 1D/2D

LectorRFID UHF (Android 11)

Pantalla más grande, mayor rendimiento en UHF

Lector RFID UHF (Android 11)

Comprometidos con un rendimiento superior en UHF

Lector UHF RFID (Android 11)

Mayor rendimiento UHF, mayor seguridad y confiabilidad

Lector UHF RFID

Ofrecer un Rendimiento Excelente de UHF a Distancia

Lector UHF RFID

Potente Lectura y Escritura en UHF

Lector Bluetooth RFID

Excelente Desempeño y Apariencia

Lector UHF RFID

Capacidad Superior de RFID UHF, Resultados Precisos y Rápidos

Lector RFID portátil

Lector portátil BT RFID

Robusta lectura y escritura RFID

Lector portátil BT RFID

Portátil y ligero con un rango de lectura UHF corto

Lector RFID Fijo

ModelosLector RFID fijo (Android 11)

Android 11 OS, múltiples Interfaces, más potente rendimiento RFID UHF

Lector/escritor RFID

Soporta múltiples estándares de protocolo con un excelente rendimiento HF&UHF

Lector RFID integrado

Diseño integrado, rendimiento RFID UHF superior

Lector de UHF Fijo

Excelente Rendimiento UHF RFID

Lector RFID de Android fijo

Excelente capacidad de RFID con el sistema operativo Android y la interfaz de varios

Lector RFID de Escritorio

Lectura RFID profesional de corto alcance, adaptada para aplicaciones de escritorio

Tabletas Resistentes

Tableta industrial 5G (Android 14)

Conexión inalámbrica 5G ultrarrápida, pantalla más grande de 10,95", con duración de batería y robustez superiores.

Tableta Industrial

Pantalla de 8 '' y 8000mAh de batería, abundantes funciones disponibles

Lectores Biometricos

Huella digital

Más potente, más Extensible, más avanzado en todos los sentidos

Capacitivo de Huella

Lectura Precisa de Huella Digital, Verificación Confiable de Identidad

Óptica de Huella

Lectura Precisa de Huella Dagital, Verificación Confiable de Identidad

Impresoras

Máquina de código de barras

Excelente impresión de código de barras, eficiente y fácil de operar

Impresora RFID

Potente impresión de códigos de barras y RFID, rápida y altamente segura

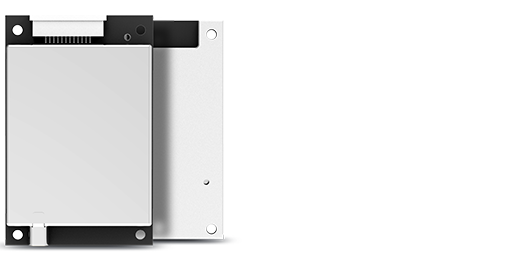

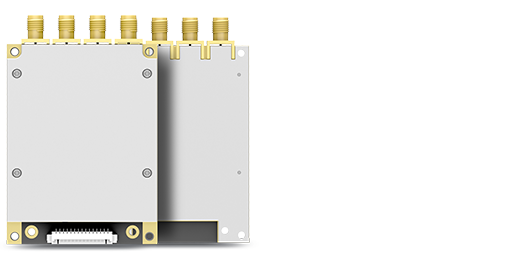

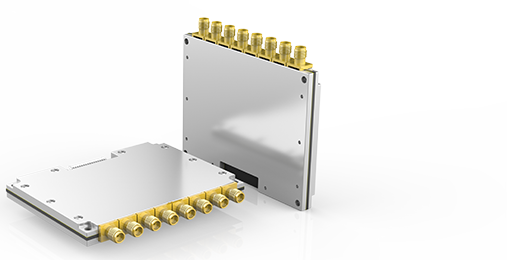

Módulo de UHF RFID

ModelosMódulo RFID UHF

Lectura de UHF con Alta Velocidad y Largo Alcance

Módulo RFID UHF

Ideal para Aplicaciones de Escaneo Intensivo

Módulo RFID UHF

Leyendo las Etiquetas Con un Rango Más Amplio

Módulo RFID UHF

Lectura de etiquetas con un rango más amplio

Computadoras Montadas en Vehículos

ModelosComputadora del Vehículo

Habilitar el cumplimiento perfecto

-

Sectores

Logística

Chainway handheld computer gives you added visibility and increased fle...

Retail

Chainway retail solution solves existing issues faced by retailers with...

Médico

Chainway mobile healthcare PDA captures accurate healthcare data in rea...

Finanzas

Chainway banking solution enables administrators to have real-time moni...

Almacén

Chainway makes your warehouse connected and smart with its barcode/RFID...

Ganadero

With Chainway PDAs, an errorless electronic profile of each animal is a...

Energía

Chainway PDAs integrated with custom-made function modules realize auto...

- Estudios de Caso

- Socios

- Soporte

- Acerca de Nosotros